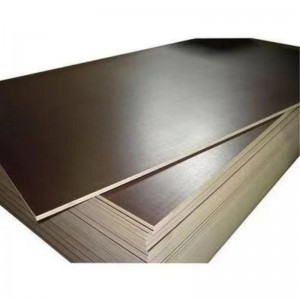

What is the film-coating process for plywood? What are the advantages of film-coated boards?

01 What is the lamination process?

To understand the board in depth, we first need to analyze its process. For readers who are engaged in decoration work or have visited the building materials market, they should be familiar with laminated boards. However, many door panels on the market today have not undergone the key processing step of lamination. This creates a significant difference from laminated boards.

Laminating process materials usually refer to the selection of high-quality milling boards. After milling and sanding, the PVC film is tightly attached to the surface using the vacuum suction principle. The materials formed by this process have excellent waterproof performance, environmental protection characteristics, and a variety of shapes and color textures.

02 Characteristics of film faced plywood

(1) Film-laminated plywood is exquisite and delicate, with both beauty and fashion. It has various shapes and can achieve both retro style and fashionable design. In addition, the board is also scratch-resistant, non-shedding, easy to care for and easy to clean, saving people trouble and effort.

(2) In terms of technology, film-laminated plywood has achieved significant improvements. It not only has the ability to process a variety of colors, but also meets the needs of intelligence, personalization and other aspects.

(3) The film-coated series is gradually gaining favor in the market. The film-coated boards are environmentally friendly, waterproof and anti-moth, flame-retardant and moisture-proof, and zero formaldehyde, and are particularly suitable for personalized home customization. In relatively humid areas, the use of film-coated boards in households has high practical value.

03 Advantages of Film Faced Plywood

The board is extremely beautiful after lamination, and the lamination presents a realistic texture. Not only are the shapes diverse, meeting consumers' needs for various styles such as retro, fashionable, and avant-garde, but consumers can also design the patterns on the lamination according to their personal preferences, making the product extremely personalized, and therefore deeply loved by consumers.

The laminated board has excellent stability. After the vacuum molding, it can be sealed as a whole on all sides without secondary edge sealing, which effectively solves the problems of debonding, deformation, moisture, etc. At the same time, it is also scratch-resistant, heat-resistant, stain-resistant, environmentally friendly and anti-fading, so it is called "defect-free board".

Post time: Apr-12-2025